- Contact: +8618610633171(whatsapp)

- Email: [email protected]

Tel: +86-395-6665556

Mob/Whatsapp/Wechat: +86 186 10633171

Email: [email protected]

Add: 7th Floor, JianYe Senlin Bandao#39, Luohe, Henan, China.

The Transfer Case, as the name implies, is a device that redistributes the power of the engine. It can output the power to the rear axle of the chassis and also output the power of the engine to other components that require power.

For example, on a pump truck, the transfer case realizes the switching of the power of the chassis engine between the rear axle and the hydraulic oil pump, which is what we often call the driving operation conversion. When the pump truck is working, all the power output by the engine is supplied to the main oil pump, constant pressure pump, boom oil pump and gear pump, providing pressure oil for pumping, reversing and boom, realizing the conversion of the chemical energy of the fuel into the engine Kinetic energy, and then convert the kinetic energy into hydraulic energy of pressure oil, such a process.

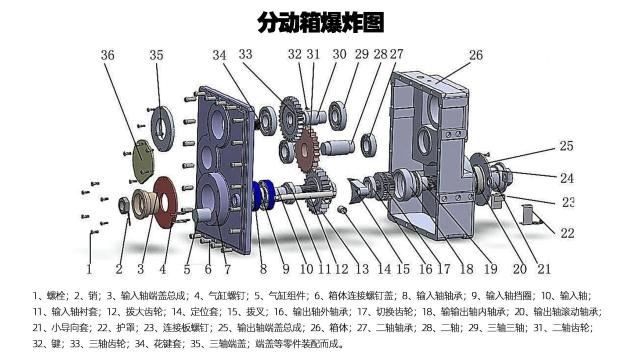

Transfer case structure and principle

The above picture is an exploded view of the transfer case. The transfer case used by the pump truck looks like a square box. The main internal components are gears, because the transfer case not only undertakes the task of power distribution, but also needs The output speed of the engine is changed by a certain gear ratio to meet the speed requirements of the hydraulic oil pump. The imported transfer case has two different models according to the transmission ratio of 0.659 and 0.825, which are suitable for different automobile chassis and hydraulic oil pumps.

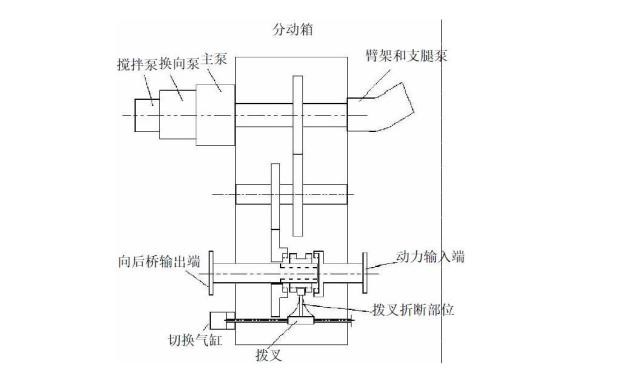

When the pump truck chassis is running, the rotational torque of the engine is transmitted to the input end of the transfer case through the transmission shaft, and the input end transmits torque to the output end of the rear axle to drive the rear axle. In this process, the power of the engine is continuously Pass to the rear bridge.

Before the pump truck starts to work, it needs to carry out the driving operation conversion, cut off the power output of it and the rear axle, and transfer the torque of the engine to the hydraulic oil pump above. This process relies on air pressure to push the piston in the cylinder, which in turn pushes the shift fork in the transfer case, realizing power redistribution. The main oil pump, boom oil pump, constant pressure pump, and gear pump start working after being powered by the engine to provide pressure energy to each hydraulic system.

Tel: +86-395-6665556

Mob/Whatsapp/Wechat: +86 186 10633171

Email: [email protected]

Add: 7th Floor, JianYe Senlin Bandao#39, Luohe, Henan, China.

Please fill in your mailbox information